I’ve recently been reading Clean Code: A Handbook of Agile Software Craftsmanship. It’s written by Robert C. “Uncle Bob” Martin of Agile software (among other) fame. The profession of computer programming sometimes struggles to be taken seriously as a profession, but programmers like Martin are true professionals. They’re dedicated to improving their craft and sharing their knowledge with others.

The book is all about traditional PC programming, but I always wonder how these same concepts could apply to my other obsession, ladder logic. I’m the first to admit that you don’t write ladder logic the same way you write PC programs. Still, the concepts always stem from a desire for Readability.

Martin takes many hard-lined opinions about programming, but I think he’d be the first to admit that his opinions are made to fit the tools of the time, and those same hard-and-fast rules are meant to be bent as technology marches on. For instance, while he admits that maintaining a change log at the top of every source file might have made sense “in the 60’s”, the rise of powerful source control systems makes this obsolete. The source control system will remember every change that was made, who made it, and when. Similarly, he advocates short functions, long descriptive names, and suggests frequently changing the names of things to fit since modern development environments make it so easy to rename and refactor your code.

My favorite gem is when Martin boldly states that code comments, while sometimes necessary, are actually a failure to express ourselves adequately in code. Sometimes this is a lack of expressiveness in the language, but more often laziness (or pressure to cut corners) is the culprit.

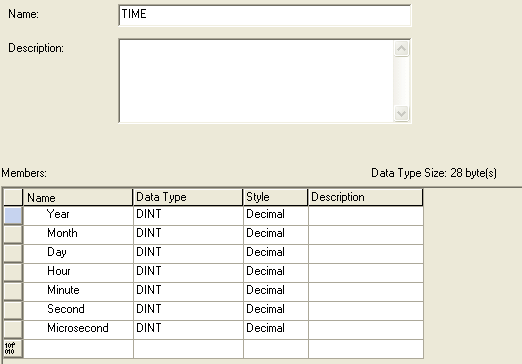

What would ladder logic look like if it was “clean”? I’ve been visiting this question during the development of SoapBox Snap. For instance, I think manually managing memory, tags, or symbols is a relic of older under-powered PLC technology. When you drop a coil on the page in SoapBox Snap, you don’t have to define a tag. The coil is the signal. Not only is it easier to write, it prevents one of the most common cardinal sins of beginner ladder logic programming: using a bit address in two coil instructions.

Likewise, SoapBox Snap places few if any restrictions on what you can name your coils. You don’t have to call it MTR1_Start – just call it Motor 1: Start. Neither do you need to explicitly manage the scope of your signals. SoapBox Snap knows where they are. If you drop a contact on a page and reference a coil on the same page, it just shows the name of the coil, but if you reference a contact on another page, it shows the “full name” of the other coil, including the folders and page names of your organization structure to find it. Non-local signals are obviously not local, but you still don’t have to go through any extraneous mapping procedure to hook them up.

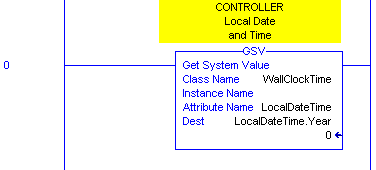

While we’re on the topic of mapping, if you’ve read my RSLogix 5000 Tutorial then you know I spend a lot of time talking about mapping your inputs and your outputs. This is because RSLogix 5000 I/O isn’t synchronous. I think it’s pointless to make the programmer worry about such pointless details, so SoapBox Snap uses a synchronous I/O scan, just like the old days. It scans the inputs, it solves the logic, and then it scans the outputs. Your inputs won’t change in the middle of the logic scan. To me, fewer surprises is clean.

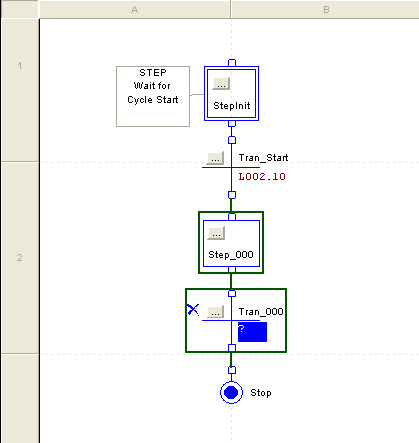

I’ve gone a long way to make sure there are fewer surprises for someone reading a ladder logic program in SoapBox Snap. In some ladder logic systems, the runtime only executes one logic file, and that logic file has to “call” the other files. If you wanted to write a readable program, you generally wanted all of your logic files to execute in the same order that they were listed in the program. Unfortunately on a platform like RSLogix 5000, the editor sorts them alphabetically, and to add insult to injury, it won’t let you start a routine name with a number, so you usually end up with routine names like A01_Main, A02_HMI, etc. If someone forgets to call a routine or changes the order that they execute in the main routine, unexpected problems can surface. SoapBox Snap doesn’t have a “jump to page” or “jump to routine” instruction. It executes all logic in the order it appears in your application and each routine is executed exactly once per scan. You can name the logic pages anything you want, including using spaces, and you can re-order them with a simple drag & drop.

Program organization plays a big role in readability, so SoapBox Snap lets you organize your logic pages into a hierarchy of folders, and it doesn’t limit the depth of this folder structure. Folders can contain folders, and so on. Folder names are also lenient. You can use spaces or special characters.

SoapBox Snap is really a place to try out some of these ideas. It’s open source. I really hope some of these innovative features find their way into industrial automation platforms too. Just think how much faster you could find your way around a new program if you knew there were no duplicated coil addresses, all the logic was always being executed, and it’s always being executed in the order shown in the tree on the left. The productivity improvements are tangible.